The application of high-quality mud facilitates efficient well drilling

Mud plays a key role in water well drilling, and rational use of high-quality mud can significantly improve rig efficiency. Mud cools the bit, carries cuttings, and stabilizes the borehole, so selecting a suitable mud formula is crucial. Adjust mud properties like density, viscosity, and fluid loss according to different geological conditions. In loose formations, increase mud density and viscosity to enhance borehole stability; in hard formations, reduce viscosity to improve slag discharge efficiency.

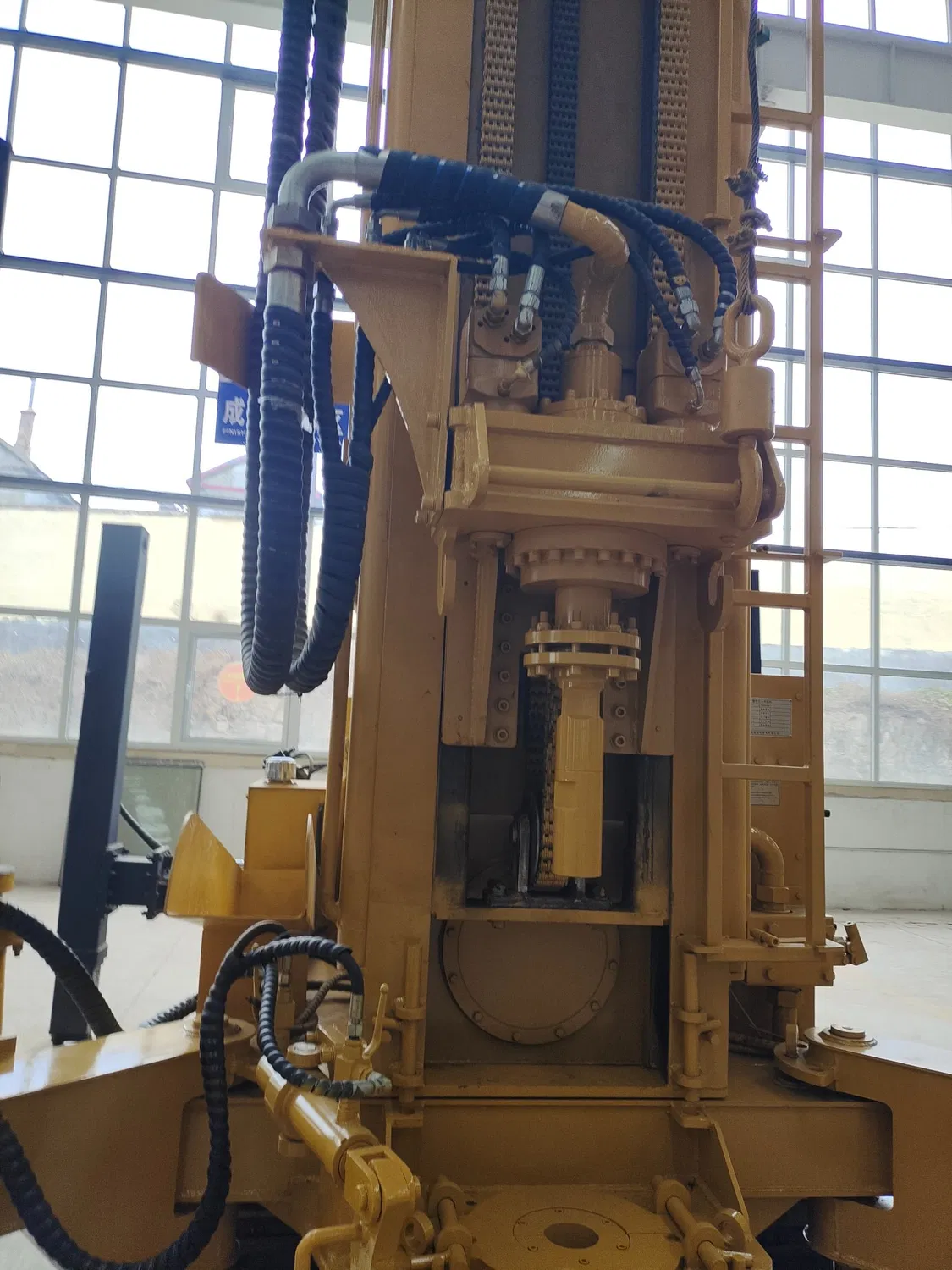

The mud circulation system also requires careful design and maintenance. Ensure the mud pump’s flow and pressure meet drilling needs, clean sediment in the mud pit promptly, and maintain mud cleanliness. Regularly test mud properties, supplement or adjust mud materials based on results, and keep mud performance optimal.

Additionally, using mud treatment agents like thickeners and fluid loss reducers can further optimize mud properties. By applying high-quality mud, reduce bit wear, improve slag discharge efficiency, prevent borehole collapse, and thus accelerate drilling speed and enhance the overall operation efficiency of water well rigs.

Bangxin өрөмдлөгийн мөр

Bangxin өрөмдлөгийн мөр