Poor welding of alloy teeth is an often-overlooked cause of frequent bit wear.

The bonding strength between alloy teeth and the bit body directly affects service life.

Issues like false welding or de-soldering make teeth loosen or fall off under formation stress,

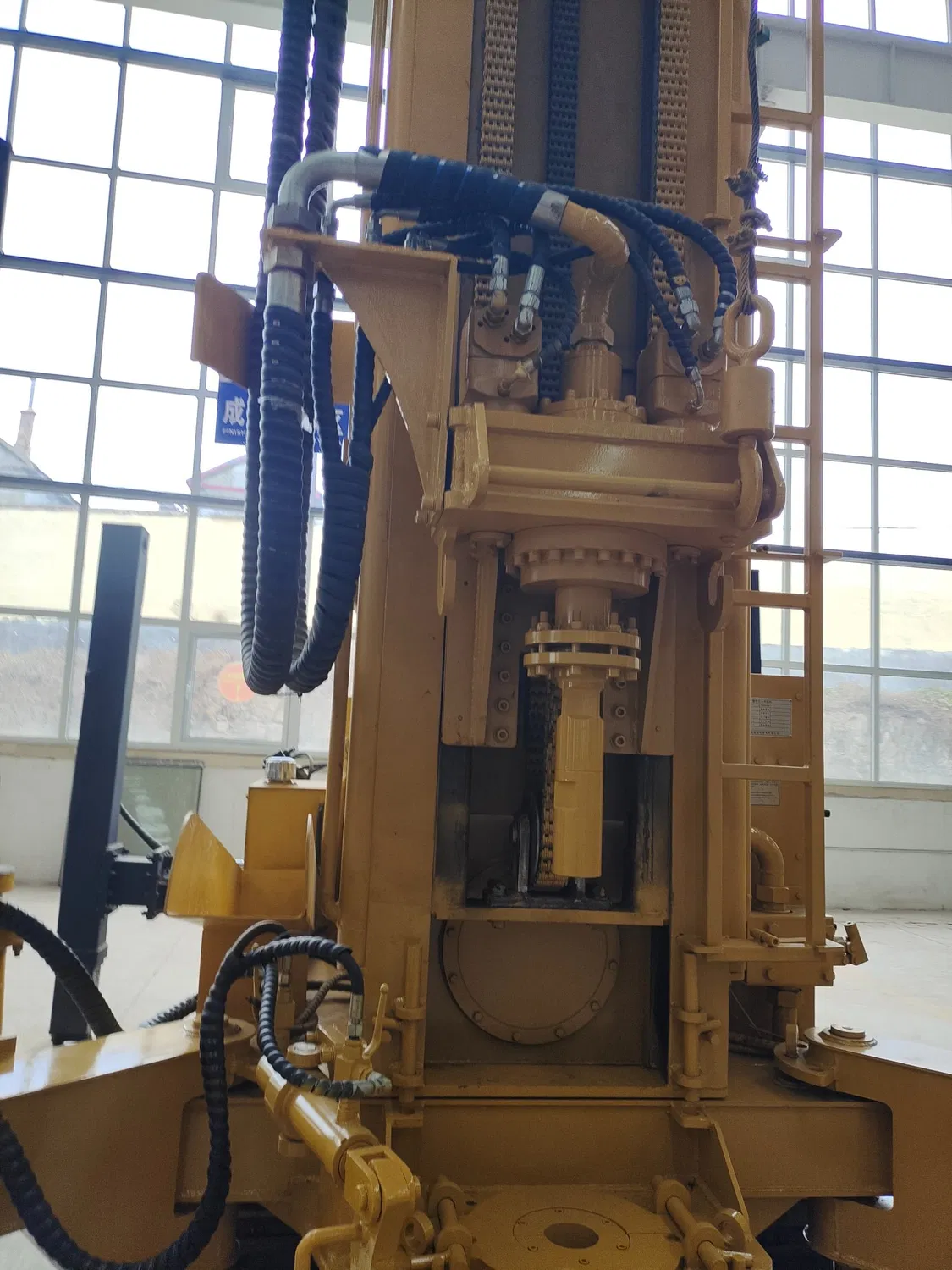

reducing cutting efficiency and accelerating wear from uneven loading.water well drilling rig

Choose drill bits from certified suppliers with advanced welding technology and strict quality checks. These manufacturers ensure reliable bonding between alloy teeth and the bit body through standardized processes.

Before using a new bit, inspect welding spots for cracks, pores, or other defects. Contact the supplier immediately for replacement if issues are found.

Examine welding areas before and after each operation for signs of looseness. If alloy teeth shift, stop usage and send the bit to a professional facility for re-welding or reinforcement.

Avoid excessive drilling parameters (e.g., high pressure/speed) that stress welds. Control settings to minimize impact forces on the bit during operation.

Perform periodic flaw detection on used bits to identify hidden welding defects. Address potential issues promptly to prevent sudden tooth detachment.water well drilling rig

Ringkasan: Prioritizing welding quality through strict sourcing, regular inspections, and operational care reduces wear-related failures. This extends bit life and cuts drilling costs effectively. Contact us for practical tips on evaluating bit welding quality in the field.

3. Routine Maintenance for Welding Integrity

3. Routine Maintenance for Welding Integrity Rig pengeboran Bangxin

Rig pengeboran Bangxin